What We Do

Outstanding Service Quality Professional Technical Expertise

Outstanding Service Quality Professional Technical Expertise

01 Energy Investment and Plant Operation

Sepmem operates 12 natural gas plants, including the largest scattered gas recovery plant in China, the Manshen LNG Plant. Sepmem seamlessly integrates engineering design with production operations, using design to guide production and utilizing operation data to optimize design, creating a positive feedback loop. With over 20 years of continuous development and innovation, Sepmem has become a leading integrated service provider and operator in the natural gas field and industrial gas treatment field in China.

![]()

02 Natural Gas ODM Services

Since undertaking its first natural gas processing service project in 2018, Sepmem has continuously secured multiple liquefied natural gas (LNG) tolling agreements with China National Petroleum Corporation (CNPC) and Sinopec. With outstanding service quality and professional technical capabilities, Sepmem's market share has steadily increased, earning an excellent reputation and positive feedback from customers. Sepmem possesses extensive experience in plant construction and operational management, taking responsibility for operations and risk management during cooperation, while the client provides feed gas and manages product sales, retaining sales revenue. This mutually beneficial collaboration model better aligns with client needs and reduces investment risks for clients.

03 Skid-mounted Equipment Supply and Technical Services

Sepmem has completed over 500 projects, covering areas such as chemical engineering, natural gas processing and treatment, industrial gas separation, new energy technology research and promotion, and the development and application of energy-saving and environmental protection equipment. With advanced process packages, proprietary technologies, and extensive project experience, Sepmem offers integrated services including process package development, engineering design, complete equipment supply, commissioning, and production operations.

04 Development of New Technologies and Materials

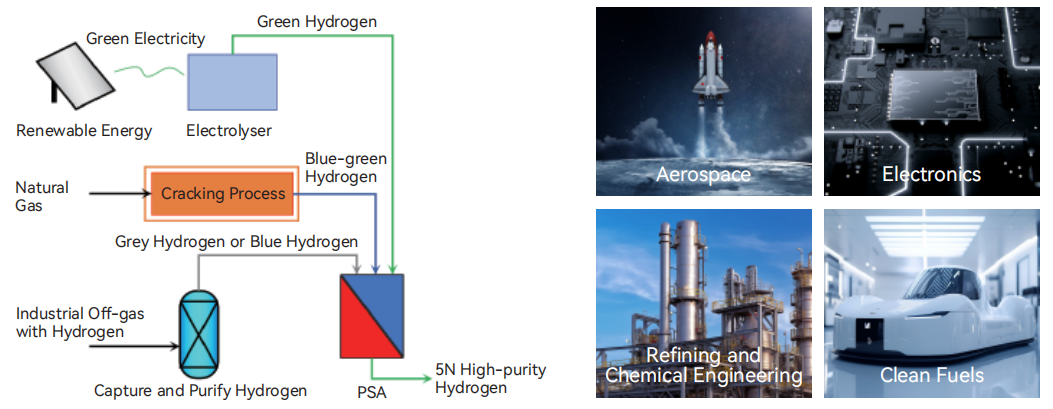

Hydrogen Energy

Hydrogen is classified into green hydrogen, blue-green hydrogen, blue hydrogen, and grey hydrogen. Green hydrogen is produced through water electrolysis powered by renewable energy sources such as solar and wind power. Blue-green hydrogen is produced by cracking hydrocarbon gases, blue hydrogen is produced via hydrocarbon reforming, and grey hydrogen is produced from coal. After pre-treatment to remove most water, oil, and solid impurities, all types of hydrogen undergo high-precision PSA (Pressure Swing Adsorption) purification to produce 5N-grade high-purity hydrogen.

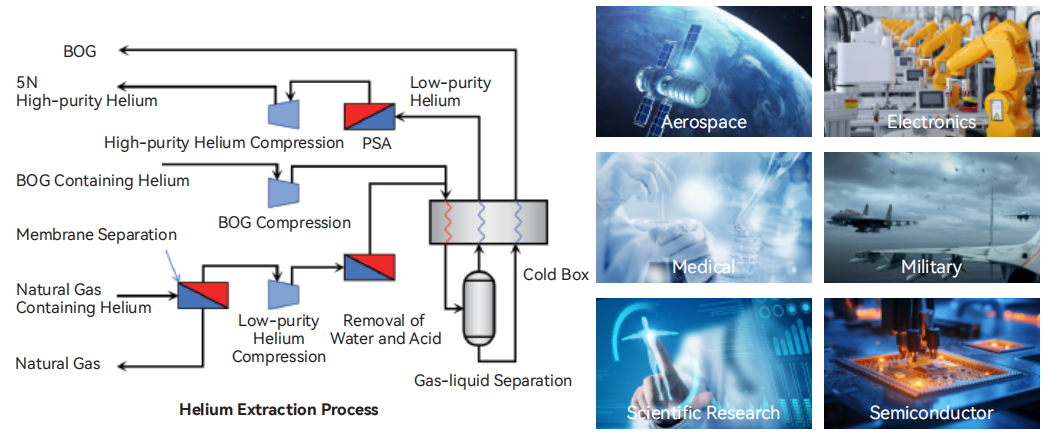

Helium

Sepmem possesses proprietary helium extraction technology, which can be designed based on gas composition, processing scale, product purity requirements, and economic considerations. The purification system allows for the selection of the number of purification cycles according to the gas source composition, with product purity reaching 99.999%. The selected instruments, valves, and other components are designed, installed, and connected to ensure reliable sealing, minimizing leakage to the greatest extent. The process is simple, and the system is equipped with an automatic switching filling system, enabling automatic filling of cylinders, tube trailers, and filling racks.

Nanocarbon

The production principle of Nanocarbon (CNOS) involves the pyrolysis of hydrocarbon gases (such as methane) at high temperatures in the presence of a catalyst to generate hydrogen and nano onion-like carbon (CNOS). Onion carbon features high specific surface area, high strength, low density, high thermal conductivity, and high electrical conductivity.